CNC Turning Services

Explore Our CNC Turning Services

When you need a one-stop machine shop for CNC turning services at the lowest costs, fast lead times, and without requirements for minimum order quantity, Huazhong may match the capacity your project demands exactly. The instant manufacturability feedback offered by Huazhong’s professional technological team allows for optimizing your part designs for the CNC turning process and fulfilling all requirements you need.

What is CNC Turning

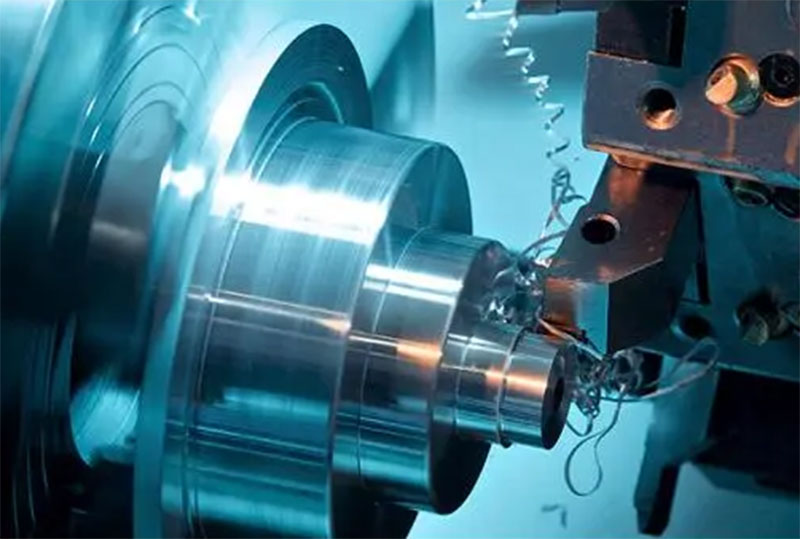

CNC turning (also known as CNC lathes) is a subtractive manufacturing process in which a stationary cutting tool removes material by making contact with the spinning workpiece to create the desired shape.

During processing, a blank bar of stock material is held in the chuck of the spindle and rotated with the spindle. Extreme precision and repeatability can be achieved under the control of computer instructions for the movement of the machinery.

When CNC turning rotates the workpiece in a chuck, it’s generally to create round or tubular shapes and achieve far more accurate rounded surfaces than CNC milling or other machining processes.

CNC Milling Materials Options

| Material | Available Varieties |

|---|---|

| Aluminum | Aluminum 5052, Aluminum 7075, Aluminum 7075-T6, Aluminum 6063-T5, Aluminum 7050-T7451, Aluminum MIC-6, Aluminum 6061-T6, Aluminum 2024-T3 |

| Brass/Bronze | Brass C360, Brass 260, C932 M07 Bearing Bronze |

| Copper | EPT Copper C110, Copper 101 |

| Plastics | ABS, Acetal [Delrin], Acrylic, G-10 Garolite, Nylon 6/6, PEEK, Polycarbonate, PTFE [Teflon], Polypropylene, Ultra-High Molecular Weight, Polyethylene |

| Steel | Alloy Steel 4130, Alloy Steel 4140, ASTM A36, Stainless Steel 15-5, Stainless Steel 17-4, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 304, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 420, Steel 1018, Steel A36 |

| Titanium | Titanium Grade 2, Titanium 6Al-4V |

| Zinc | Zinc Sheet Alloy 500 |

CNC Turning Parts Gallery